Plate heat exchangers are used not only as single-phase heat exchangers but also as evaporators and condensers due to their compact design and cost efficiency in combination with an outstanding thermohydraulic power density. The already very efficient apparatuses could be further improved in terms of two-phase heat transfer by functionalizing the surface of the plates using femtosecond laser pulses. The application area for such highly efficient apparatuses with low degrees of freedom is, for example, the use of temperature differences in seawater from different depths (Ocean Thermal Energy Conversion OTEC).

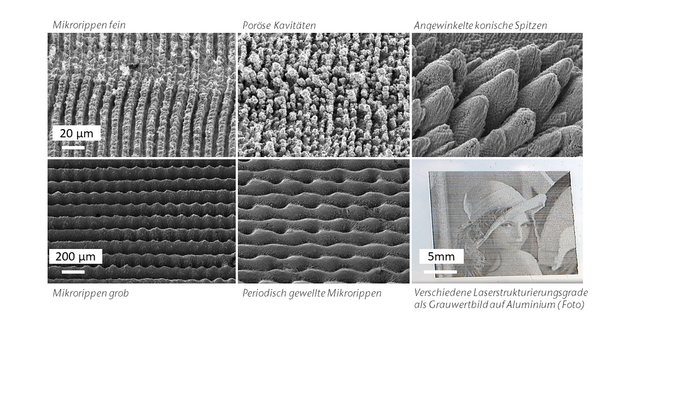

The surface changes possible by means of femtosecond laser pulses are on the one hand of a geometric nature in the nano- and micrometer range, and on the other hand of a chemical nature due to the possible incorporation of foreign atoms (see figure for exemplary structures). An increase in efficiency in the heat transfer performance of these functionalized surfaces is expected. An important aspect of the functionalization of surfaces with regard to heat transfer is the wetting behavior. If a hydrophobic surface is produced by the laser process, an increased number of nucleation sites and a correspondingly increased number of bubbles can be expected during evaporation. During condensation, a hydrophobic surface can force mixed or droplet condensation, which has significantly higher heat transfer coefficients. The use of lasers also allows flexible modification of the local structure, so that localized and locally variable surface properties can be applied along the sheet. The photograph at the bottom right of Figure 1 illustrates the possibilities for local structure definition offered by the laser process.

©

LUH-IfT

©

LUH-IfT

The aim of the research project is a fundamental understanding of the thermohydraulic effect of laser-structured metallic surfaces during boiling and condensation, as well as their systematic fabrication for increasing the efficiency of corresponding plate heat exchangers. The research project is carried out in cooperation with the Research Center Energy Storage Technologies (EST) of the Clausthal University of Technology, which is responsible for the structuring of the surfaces and the investigation of the relationships between process parameters and structural properties. Subsequently, a systematic investigation of the influence of the process parameters in the femtosecond laser process on the thermal and fluid dynamic properties of laser structured surfaces will take place at the IfT. For this purpose, a large number of structured surfaces will be produced, investigated by measurement and evaluated. The methodological approach envisages a stepwise reduction of the pool of samples based on the knowledge gained while simultaneously increasing the metrological effort for characterization. Finally, a comprehensive evaluation of selected structures in plate heat exchangers on a pilot plant scale is planned. In addition to the measurement of quasi-local heat transfer coefficients, a test of the temperature oscillation method (TOIRT) for two-phase heat transfer problems is planned. The TOIRT method allows non-contact measurement of heat transfer coefficients in channel flows by determining the phase offset between an imposed oscillating heat flux (laser/halogen radiator) and the resulting temperature response on the outside of the channel. Correlations can be made from the measured data with respect to both the pressure drop and the heat transfer coefficient.

Processing

30823 Garbsen